Control Valves: Your Key to Success in an Automation Career

Alright folks, let's dive into the fascinating world of control valves. Now, I know what you're thinking – valves? Seriously? But hold your horses, because these little guys are the unsung heroes of automation, and understanding them could be your ticket to a successful career in this exciting field. So, let's ditch the stereotypes and explore why control valves are more than just plumbing, they're the key to unlocking a world of opportunity.

Control Valves: The Unsung Heroes of Automation

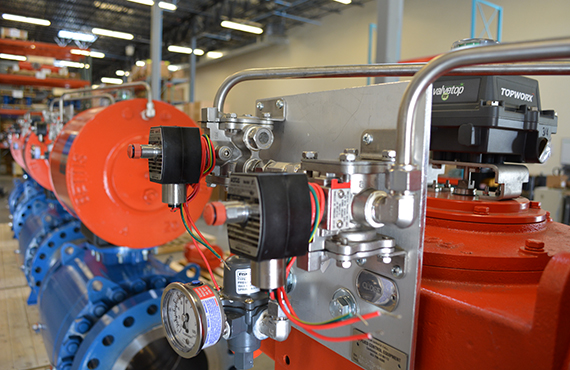

Picture this: a vast industrial plant, humming with activity. Machines whirring, conveyor belts chugging along, and liquids and gases flowing through a complex network of pipes. It's a symphony of coordinated movement, all orchestrated by one crucial component: control valves. These unassuming devices might not get the spotlight, but they're the backbone of automation. They regulate the flow of fluids and gases, ensuring that processes run smoothly, efficiently, and safely. Without them, industrial plants would grind to a halt, power grids would falter, and our modern way of life would be impossible. Learning opportunities abound when exploring how these devices function and their significance in various applications. The question staring us in the face is this – how do they work and why are they so important?

Control Valves Functioning & Importance

It's not rocket science, but it's definitely a fascinating blend of mechanics and ingenuity. At their core, control valves are pretty simple. They're basically adjustable valves that can open or close to control the flow of a fluid or gas. But the real magic lies in how they're controlled.

Think of it like this: imagine you're driving a car. You use the gas pedal to control the flow of fuel to the engine, which in turn controls the speed of the car. A control valve is kind of like that gas pedal, but instead of controlling the flow of fuel, it controls the flow of whatever fluid or gas is running through the system. Now, there are different types of control valves, each with its own unique design and function. Some valves use a rotating ball or disc to control the flow, while others use a sliding gate or a diaphragm. But they all have one thing in common: they respond to signals from a control system, which tells them how much to open or close. These signals can come from a variety of sources, such as sensors, timers, or even human operators. The control system takes this information and uses it to calculate the optimal flow rate for the process. It then sends a signal to the control valve, which adjusts its position accordingly. This constant feedback loop is what makes control valves so important for automation. They allow systems to respond dynamically to changes in their environment, ensuring that processes run smoothly and efficiently. For example, in a chemical plant, control valves might be used to regulate the temperature of a reactor. Sensors would monitor the temperature and send that information to a control system. If the temperature gets too high, the control system would send a signal to a control valve to open, allowing more coolant to flow through the reactor and bring the temperature back down.

And they are more than just plumbing!

Okay, so control valves regulate flow. Big deal, right? Wrong! These little guys are way more than just glorified plumbing. They're the brains behind many automated processes, constantly monitoring and adjusting to maintain optimal conditions.

The Automation Advantage: Why Control Valves Are in High Demand

The world is becoming increasingly automated, and control valves are at the heart of this revolution. They're the key to optimizing processes, reducing costs, and improving safety. As a result, the demand for skilled professionals who understand control valve technology is skyrocketing. Companies are looking for people who can design, install, maintain, and troubleshoot control valve systems. They need individuals who can analyze data, identify problems, and come up with innovative solutions. If you have a knack for problem-solving and a passion for technology, a career in control valve automation could be your calling.

How to Master Control Valve Technology

So, how do you become a control valve whiz? It starts with a solid foundation in engineering principles, but it doesn't end there. You'll need to understand the different types of control valves, how they work, and how to select the right valve for the right application. You'll also need to learn about control systems, instrumentation, and data analysis. And don't forget about the soft skills, like communication, teamwork, and problem-solving. These are essential for any successful automation engineer.

Wrapping Up

If you're looking for a challenging and rewarding career with plenty of growth potential, look no further than control valve automation. It's a field that's constantly evolving, with new technologies and applications emerging all the time. By mastering control valve technology, you'll be in high demand in a wide range of industries. You'll have the opportunity to work on cutting-edge projects, solve complex problems, and make a real impact on the world.

Ideas, requests, problems regarding TWiki? Send feedback